About us and Bamboo Charcoal

-

About Bamboo Charcoal

Charcoal with excellent purification properties

Bamboo charcoal is made by slowly roasting bamboo in a kiln that reaches temperatures over 1000 degrees Celsius. This bamboo charcoal has excellent purification properties and is valued not as a fuel, but as a raw material for cosmetics and food additives. The bamboo charcoal from Isesho Store is characterized by its high hardness and mineral content. It is a unique type of bamboo charcoal that makes a distinct metallic sound, like a "keen," when struck.

-

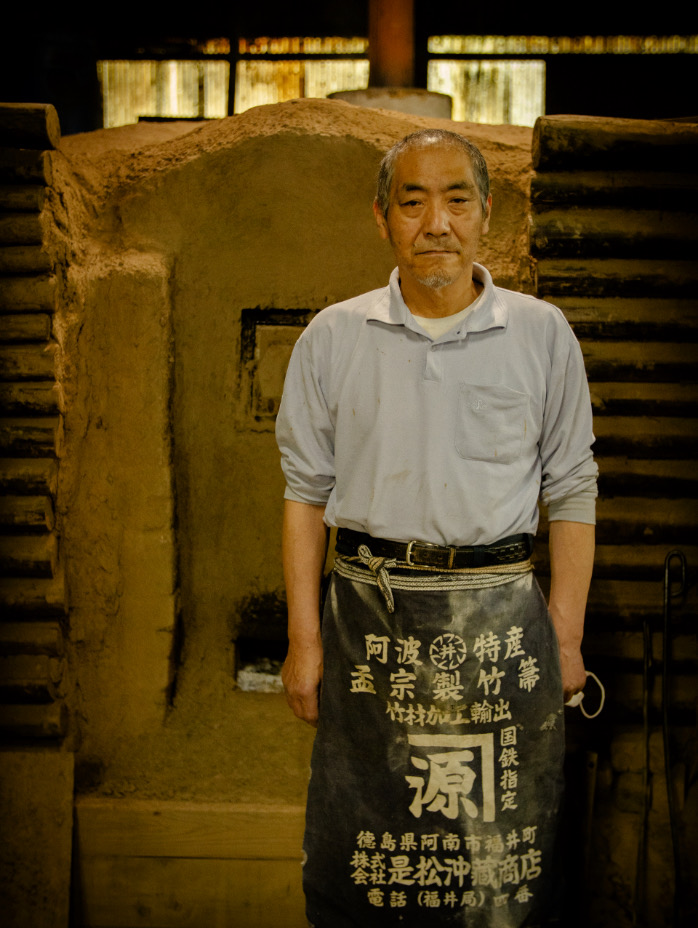

About Korematsu shouten

Factories in Anan City, Tokushima Prefecture

We are located in a bamboo forest in Anan City, Tokushima Prefecture, Shikoku, a region known as "Bamboo Town." They have been in the bamboo business for over 100 years and began making bamboo charcoal about 25 years ago. The store's name, "'┐'Kane-gen," comes from the original name "Kane-gen Shouten," established by the first generation, Korematsu Genzo. Even though the company name has changed, they continue to use the original name. "Kane" signifies straightforwardness, reflecting their commitment to conducting business as straightforwardly as bamboo grows. This principle is still our foundation.

-

About Charcoal Kiln

Repaired and cherished over and over

An indispensable part of bamboo charcoal production is a charcoal kiln that can withstand heat up to 1,000 degrees Celsius. Today, there are few craftsmen left who can make charcoal from scratch. When we started making bamboo charcoal, we worked with the charcoal kiln craftsman of the time to build the kiln, which we continue to use with great care and repeated repairs.

-

Production

Always keep an eye on the kiln.

Our bamboo charcoal making process is very delicate, and even the slightest error in temperature control will not produce good charcoal. Even with our thorough knowledge of bamboo, we need to be aware of what is going on in the kiln at all times, as conditions are constantly changing due to factors such as weather and humidity.

Product

-

Plate shaped Charcole

This is bamboo charcoal shaped into板状. It is used for various purposes such as purifying drinking water, cooking water, aquarium filtration, and for dehumidification and deodorization.

-

Unshaped Charcole

This is bamboo charcoal made in its natural shape. It is used for various purposes, including as a flower vase, floral arrangement material, and interior decoration.

-

Granular Charcoal

This is bamboo charcoal in granular form. It is used for drinking water, bathing, and many other purposes. Available in 20 mm, 5 mm, and 3 mm sizes.

-

Powder Charcoal

This is bamboo charcoal in a fine powder form. It is used as a raw material for food additives and cosmetics. It is available in 15 microns and 5 microns.

-

Bamboo Vinegar

This is a liquid distilled from the smoke of roasted bamboo. Some versions have had the tar removed to become transparent. It is used for various purposes, including deodorization, sterilization, and gardening.

*For inquiries regarding purchases or any of our products, please contact us at the email address provided in the contact section.

Process

-

1. Collect bamboo

The raw material, moso bamboo, is purchased straight from nearby bamboo farmers.

-

2. Splitting and sorting

Bamboo is split evenly and sorted. Good bamboo is sent to the next process.

-

3. Drying

Bamboo is placed in an airy environment for three to six months to dry.

-

4. Re-sorting

The dry bamboo is checked for quality and moisture content and sorted again.

-

5. Smoking

Bamboo is smoked with heat for 4-5 days to equalize the moisture content in a kiln.

-

6. Increasing the temperature

The the temperature is raised to warm the bamboo with air for 3-4 days.

-

7. Air blockage

The temperature is rapidly increased and the material is heated for about 4 hours (refining). Finally, the process is completed by completely shutting off the air to finish the carbonization.

-

8. Complete

After 4 hour carbonization process, charcoal is cooled off and removed from the klin.

-

9. Processing

Bamboo charcoal is processed according to its intended use, and finally inspected.

We Accept Inquiries for Bamboo Collection

If you have bamboo in Tokushima Prefecture that has been cut down and you are unsure how to dispose of it, please feel free to contact us for consultation.

Contact

・Please reach out via the email address listed in the inquiry section below.

・Types of bamboo we can collect: Moso bamboo

“Making Anan a Bamboo Town Again"

We have been engaged in bamboo-related businesses for generations. The knowledge and experience about bamboo we have gained for long time arrows us to make bamboo charcoal for a living.

Even now, there are times when the results are not as good as I would like them to be, and I continue to learn about bamboo through trial and error every day.

I would like to continue making bamboo charcoal as long as possible and continue to do what I can so that Anan City in Tokushima Prefecture will once again be called “Bamboo Town. We hope that many people will come to Anan City and experience the charm of bamboo.

Tokohito Korematsu

Contact(K's Bamboo)